Posted on 8/18/2017 by Da-Lite Team

Kris Carney moved to the Warsaw, Indiana, area in 1985 when her husband got a job in IT. A neighbor got her an interview at Da-Lite. The company needed someone who knew how to read blueprints, and Carney fit that description.

Da-Lite was putting a foot into the overhead projector business at the time. Carney worked on the floor making carts and projectors for several years. She quickly moved positions until starting in the Fast-Fold division, which she ran for 20 years. For the past seven years, she’s been a design center specialist.

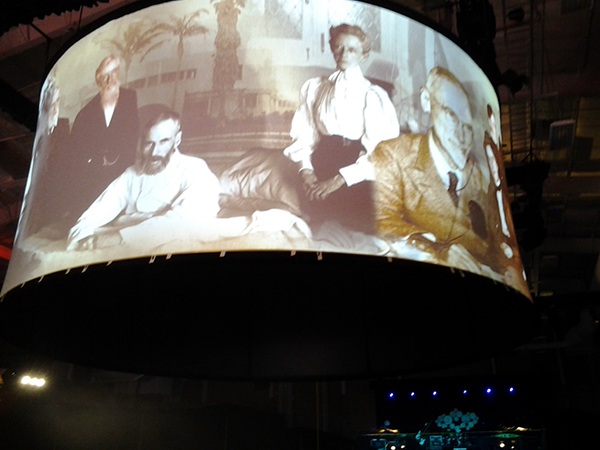

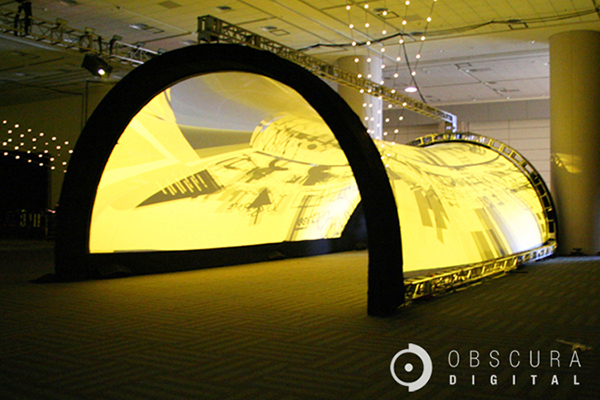

Carney recently retired after more than 30 years at Da-Lite. She’s seen the evolution of screens, particularly in the design center, where she helps to create solutions for out of the box requests – star shaped screens, curves, domes and extremely large screens.

“Anything that’s not a 90-degree angle is a challenge,” Carney said. “Sometimes it takes a couple tries.”

Carney is traditional in her approach – using drawings, cardboard, foam, duct tape and origami to figure out the best way to create large scale screens with unusual shapes. From as small as origami models to putting together 150-foot-long screens in a rented airplane hanger (“They aren’t light when they get that big”), Carney’s job sees projects through from end to end, even down to the details of how to fit a large screen onto a plane for shipping.

For Carney, innovation means change.

“We’ve changed fabric a lot in the 30 years I’ve been here,” she said. “The material was stiff and heavy grain on the front when I started here. The material is now softer, more pliable, easier to do some of the special stuff. There’s a uniqueness in how the material is reacting to things.”

The design center where Carney has spent her last six years uses the many surface options to create unique screens. Industry trends have led to bigger screens and specific simulation environments for helicopter or police training. In 2015, she helped to create the sunglasses-shaped screen for the Da-Lite LDI booth.

“Using what you have is the fun part,” she said. “Trying to use what you have rather than buying something. You stretch yourself to accommodate someone else’s uniqueness.”

Domes have been a particular challenge in simulation applications. Five panels get seamed together in a curved surface that is held to the inside of the dome by vacuum. Putting together the seams just right so they match the dome surface is painstaking work with a custom jig. And it leads to further ideas.

“Now that you know you can curve the fabric, that’s another arena that can be addressed,” Carney said. “I can see that being something you can build into something else someone might want. One thing leads to another.”

Carney is looking forward to checking in on her brother who lives in Huntington as well as travel to see other siblings around the US. She also plans to take up flute and painting. Once a year, she travels to do volunteer work in Kentucky.

“It’s fulfilling work and we all have a good time. I hope to continue that as well,” she said.

All News

All News